Normally, students in the third quarter of the Introduction to Biology series would be dissecting sheep or beef hearts in a lab at the University of Washington Bothell.

“We get a really good feel for what the heart is like,” said Dr. Salwa Al-Noori, associate teaching professor in the Division of Biological Sciences. “Dissecting is a really great way to learn.”

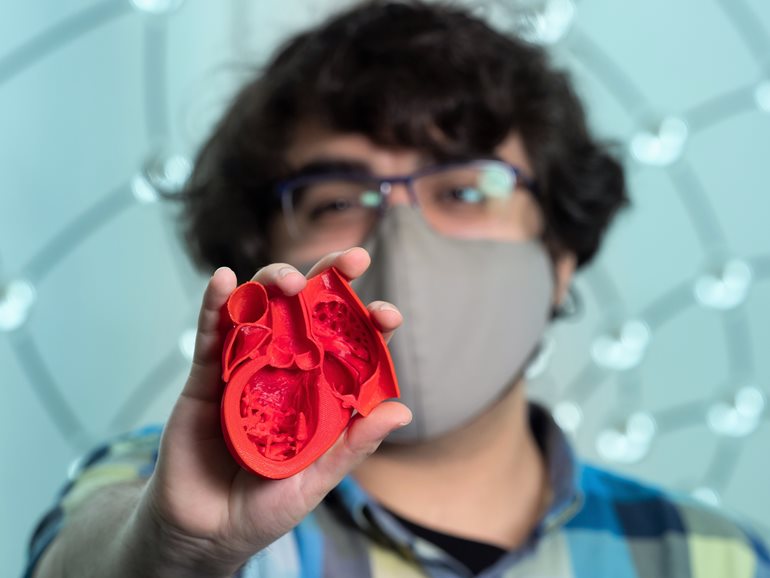

After the coronavirus pandemic hit, Al-Noori, taught the course remotely a year ago, using videos. This spring, Al-Noori worked with lab managers in the School of STEM to give students a physical object to study at home. In collaboration with the Makerspace, they used its 3D printers to make anatomically correct human hearts.

“Having that model in your hand is not the same as dissecting a fresh heart, but it really is an ‘up’ from what we would be doing using videos alone,” Al-Noori said.

Home is where the heart is

The plastic hearts exemplify how lab managers support faculty to give students the best learning tools, whatever the circumstances, said Al-Noori, who has been teaching at UW Bothell since 2013. The project developed from her conversations with Kelly Carter-Lynn, biological sciences lab coordinator; and Christy Cherrier, STEM science lab manager.

“It was me having the wish list, and Kelly and Christy making it happen. I said, ‘I want to show this,’ and they showed me something that supported that learning,” Al-Noori said.

Other collaborators were Jacob Roth, mechanical engineering lab coordinator; and Jesus Govela, administrative lead for the Makerspace. Govela (’19 Applied Computing) had used the Makerspace as a student and was familiar with the 3D printers. He and Roth set up the machines to print hearts.

“The hardest part was figuring out how to efficiently make them so we’re not wasting time or material,” Govela said.

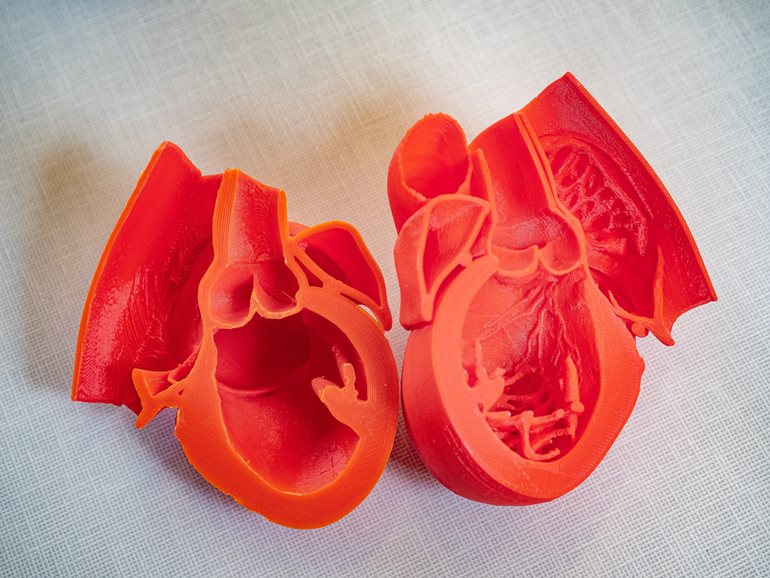

Have a heart in halves

They found their heart on thingiverse.com, an open platform with more than two million 3D print projects. Using three printers, Makerspace printed nine hearts a day in various colors — purple, blue, orange and grey — depending on the spool of filament source material. The hearts were printed in halves that fit together. Separating the halves reveals the vessels, chambers and valves.

“I know a little bit what it’s like studying remotely,” Govela said. “I’m glad we can help make that a little easier for the students.”

Although the plastic model doesn’t have the texture and feel of a fresh heart, “this is a really good substitute,” said Al-Noori.

Students do not get to cut the heart apart, but they have it available for longer than at a two-hour lab to study. And they can hold on to their hearts for future courses in anatomy or physiology. Those are benefits Al-Noori would like to extend past the pandemic. She also would like the Makerspace to print other organs, such as kidneys and eyes, with lab fees covering the cost.

Heart’s desire for everyone

In the past, Al-Noori used Makerspace 3D printing for an item or two for her research group. This was the first use for an entire course with about 100 students. With the lab coordinators and Makerspace, she was able to give each student a heart at far less cost than a biological supply company would have charged.

Lab coordinators routinely collaborate with faculty on the tests and experiments students conduct. Faculty come up with the ideas; coordinators review them for safety and feasibility, buy supplies and set up the labs. They make science happen at more than a half dozen labs in Discovery Hall and the Beardslee Building. The greenhouse at the Sarah Simonds Green Conservatory also holds some labs.

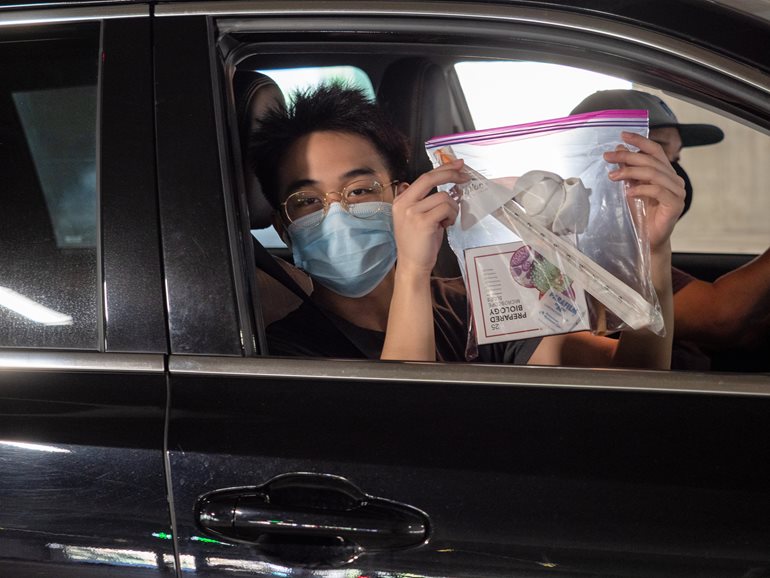

Throughout the pandemic, the coordinators for biology, chemistry, physics and engineering have been assembling lab kits with materials and equipment that students use at home. Students pick up their kits at the beginning of the quarter in a drive-thru in the south parking garage. “All of the planning and organization is a huge task for lab staff,” Al-Noori said.

From the “pandemic online learning point of view,” Carter-Lynn said, lab managers have been implementing the novel ways faculty devise to teach science online. “We’re still finding creative ways to help students get the best experience we can provide them.”