By Douglas Esser

The 20-foot container recently parked near the Truly House is not part of some new University of Washington Bothell construction project. It’s cooler than that – solar power cool.

The big metal box is being transformed into a solar-powered cooler that will be moved to a farm in Woodinville to help keep fresh-picked vegetables nutritious and safe to eat.

Making it all work is the capstone projects for a team of UW Bothell mechanical engineering seniors.

This four-member “solar cooler” group has the most complex project from a systems engineering project, said Pierre D. Mourad, associate professor, School of STEM, engineering and mathematics division.

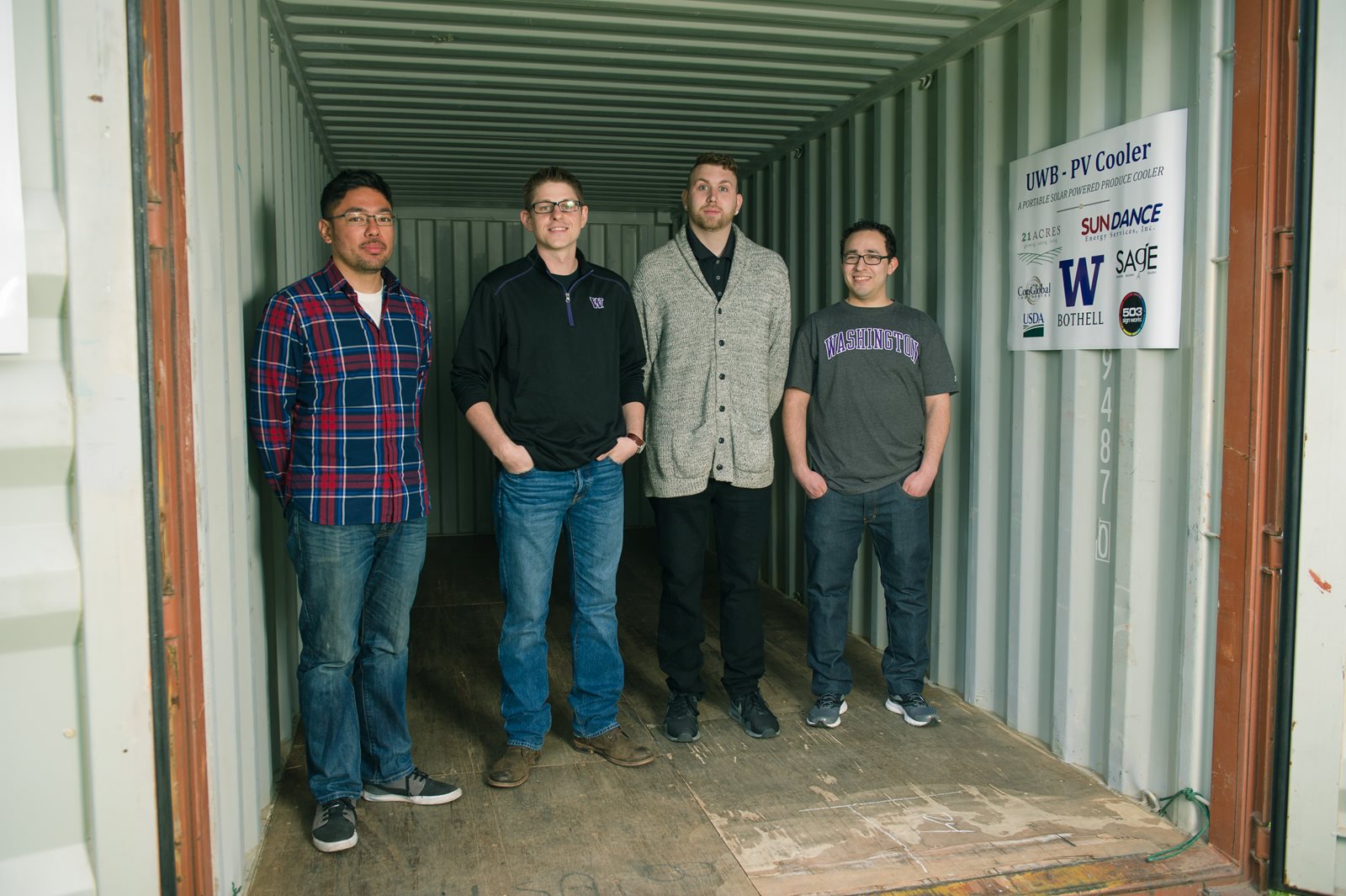

Photo: The students have taken on specific roles for the project (left to right): Jake Schriner, lead electrical engineer; Luis Alvarado, the chief financial figure; Elliott Vega, lead mechanical engineer; and Robby Shaffer, project manager.

They have a budget of about $23,000 through a grant of U.S. Department of Agriculture money from 21 Acres, a nonprofit demonstration farm in Woodinville that promotes fresh, local, sustainable farm products.

Director of Operations Kurt Sahl says the project is important because it will provide refrigeration at a location that does not have electricity, the SAgE Student Farm.

The 4-acre Sustainable Agriculture Education farm along the Sammamish River is a joint operation of Edmonds Community College, Skagit Valley College and Seattle Central College. It teaches sustainable and organic practices for urban and small farm agriculture. SAgE is a UW Bothell community partner through the Office of Community-Based Learning and Research.

Farm manager Perry Acworth brought the solar-powered cooler idea to UW Bothell.

“We were throwing out vegetables that were rotting because of a lack of cooler access,” she says.

A third partner is Viva Farms of Skagit County, also an incubator for new farmers.

“The goal is that all three entities’ farms will be GAP (Good Agricultural Practices) certified operations in 2016,” Acworth says. “If it weren’t for the students, I’m not sure we could do this within the budget constraints of the USDA grant.”

Having a cooler in the field to immediately refrigerate fresh-picked fruits and vegetables preserves nutrients and reduces the growth of bacteria that can contaminate food, says Alvarado, the financial manager for the project. Solar power makes the unit sustainable and transportable. If it’s successful, the opportunities are boundless.

“I think there would be a demand, if not for this design, then for what we’re learning from this design,” says Shaffer.

Building and delivering a product that promotes safe and locally sourced food is not a typical mechanical engineering course. This project arose out of a mechanical engineering class taught by Associate Professor Steve Collins.

The project is different from a class, says Schriner, “real money, real clients.”

The educational value comes from the project management experience: the budget, the timeline, talking with companies, managing client expectations. The result is “something we’re proud to put on our resumes,” says Shaffer.

The hands-on experience is “what I want as a student, and that’s what faculty is trying to provide” Shaffer says, “and that’s what employers want too.”

“I think project-based work is what I see a lot of companies looking for — that you can actually produce,” he says. “You've done a real-world project. So I think that's a huge advantage.”

The solar cooler team is installing insulation and equipment while the container is on campus.

“The big thing we have to do is build the inside now,” says Schriner. “It’s been great seeing how everything works together.”

Sundance Energy Services, a heating and cooling contractor located in Bothell near the campus, is designing the solar array that will be installed once the cooler is on the farm. The support of Sundance as a community partner “is a huge asset to the project,” Shaffer says.

The design is intended to cool a 14-foot portion of the interior down to 38 degrees using a heat pump powered by batteries that are replenished by solar power.

The student team also will deliver some “best practices” advice that sound like something your mother would say when you’re standing in front of the refrigerator, looking for a snack. Close the door! And preserve that precious cold air as much as possible.